Automotive bearings are part of the industrial bearings, automotive bearings in addition to some general bearings, there are some special bearings (such as clutch release bearings, wheel bearings, etc.), these special bearings have their own standards. Special bearings due to special conditions will have some special requirements, resulting in increased production costs, price and quality are higher than the general bearings. At present, the car is moving towards light weight, compact structure, solid, high power, good acceleration performance, comfortable, durable, high reliability and other aspects of development. In addition, due to the progress of electronic control technology, the car is also moving towards low energy consumption, good driving performance, convenient and other practical performance direction, so rolling bearings as an important component of automotive support, which must adapt to this development trend.

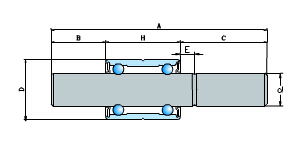

Clutch release bearing is an important part of the car, installed in the clutch and transmission between the clutch pressure plate, the separation lever and the engine crankshaft synchronous operation, in order to ensure the clutch can be smooth, soft, reduce wear and tear, extend the clutch and the whole The life of the drive train requires the separation of the bearing by allowing the separation lever to rotate axially along the clutch output shaft. Clutch separation bearing disassembly is more complex, time-consuming, this, the choice of high reliability, quality guaranteed bearings, and in the use of reasonable maintenance and maintenance, can extend the bearing life and improve the user's economic efficiency.